According to different uses of threads, it can be divided into:

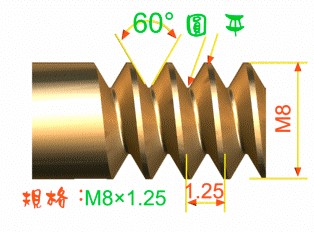

1. International Metric Thread System:

Which is also same Chinese standard CNS thread. The top of the tooth is flat, which is easy to turn, and the bottom of the tooth is arc-shaped to increase the thread strength. The thread angle is 60 degrees, and the specification is represented by M.

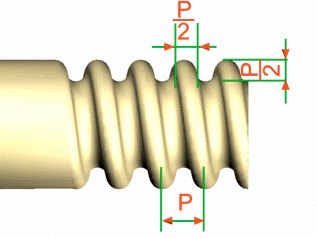

Metric thread can be divided into two types: coarse thread and fine thread.

The notation is M8x1.25. (M: code, 8: nominal diameter, 1.25: pitch).

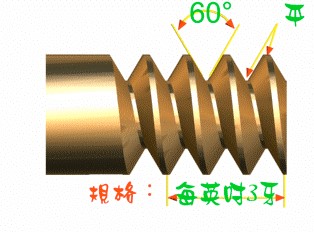

2. American Standard Thread:

Both the top and root of the thread are flat and the strength is better. The thread angle is also 60 degrees, and the specification is expressed by a few teeth per inch.

This kind of thread can be divided into three grades: coarse thread (NC); fine thread (NF); extra fine thread (NEF).

The notation is like 1/2-10NC. (1/2: outer diameter; 10: number of teeth per inch; NC code).

3. Unified Thread:

Jointly formulated by the United States, Britain, and Canada, it is the commonly used inch thread at present. The thread angle is also 60 degrees, and the specification is expressed by a few teeth per inch.

This kind of thread can be divided into coarse thread (UNC); Fine teeth (UNF); Extra fine teeth (UNEF).

The notation is like 1/2-10UNC. (1/2: outer diameter; 10: number of teeth per inch; UNC code)

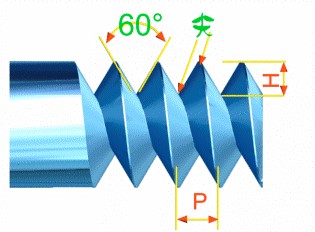

4. Sharp V Thread:

The top and roots are both pointed, weak in strength, and not often used. The thread angle is 60 degrees.

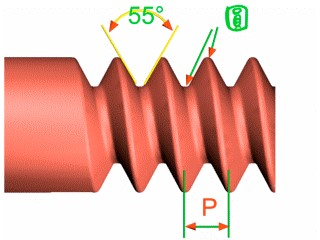

5. Whitworth Thread:

Thread adopted by British National Standard. The thread angle is 55 degrees, and the symbol is "W". Suitable for manufacturing by rolling method.

The notation is like W1/2-10. (1/2: outer diameter; 10: number of teeth per inch; W code).

6. Knuckle Thread:

It is the standard thread defined by the German DIN. Suitable for the connection of bulbs and rubber tubes. The symbol is "Rd".

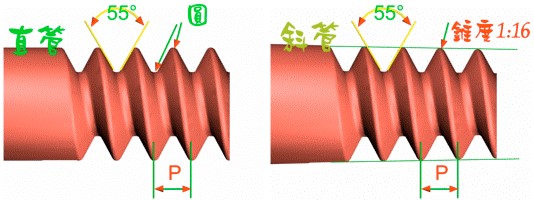

7. Pipe Thread:

Threads used to prevent leakage are often used to connect gas or liquid pipe fittings. Thread angle is 55 degrees, which can be divided into straight pipe (thread code "P.S., N.P.S.") and oblique pipe (thread code "N.P.T."), the taper is 1:16, which is 3/4 inch per foot.

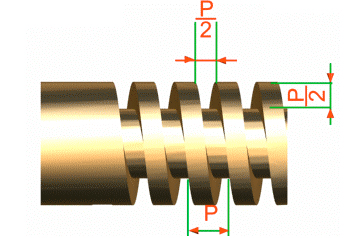

8. Square Thread:

The transmission efficiency is high, second only to the ball thread, and it cannot be adjusted with a nut after wear, which is a disadvantage. Generally used for the screw of the vise and the screw of the crane.

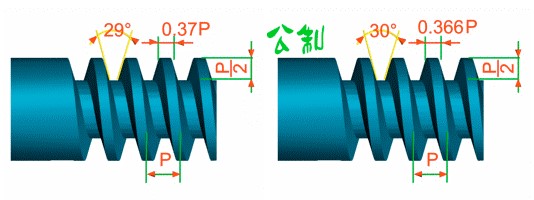

9. Trapezoidal Thread:

Also known as Akem thread. The transmission efficiency is slightly lower than that of the square thread, but it can be adjusted with a nut after wear. The metric thread angle is 30 degrees, and the inch thread angle is 29 degrees. Generally used for the lead screw of a lathe. The symbol is "Tr".

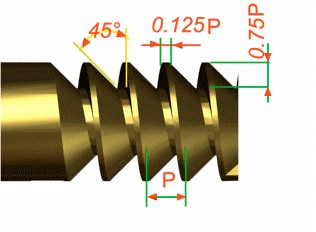

10. Buttress Thread:

Also called oblique thread, it is only suitable for unidirectional transmission. Such as screw jacks, presses, etc. The symbol is "Bu".

11. Ball thread:

The thread with the best transmission efficiency is difficult to manufacture and the cost is extremely high. It is used in precision machinery. Such as the lead screw of a CNC machine tool.

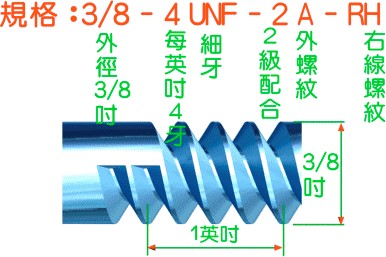

Representation of inch bolts

LH 2N 5/8 × 3-13 UNC━ 2A

(1) LH is left-hand thread (RH is right-hand thread, which can be omitted).

(2) 2N double thread thread.

(3) 5/8 inch thread, outer diameter 5/8 ".

(4) 3 bolt length 3".

(5) 13 thread counts 13 teeth per inch. (6) UNC uniform standard thread coarse pitch.

(7) Level 2 fit, external thread (3: tight fit; 2: middle fit; 1: loose fit) A: external thread (can be omitted) B: internal thread

Inch thread:

The size of the inch thread is usually expressed by the number of threads per inch of length on the thread, referred to as "number of threads per inch", which is exactly equal to the reciprocal of the thread pitch. For example, a thread with 8 teeth per inch has a pitch of 1/8 inch. The representation of inch thread is as follows: