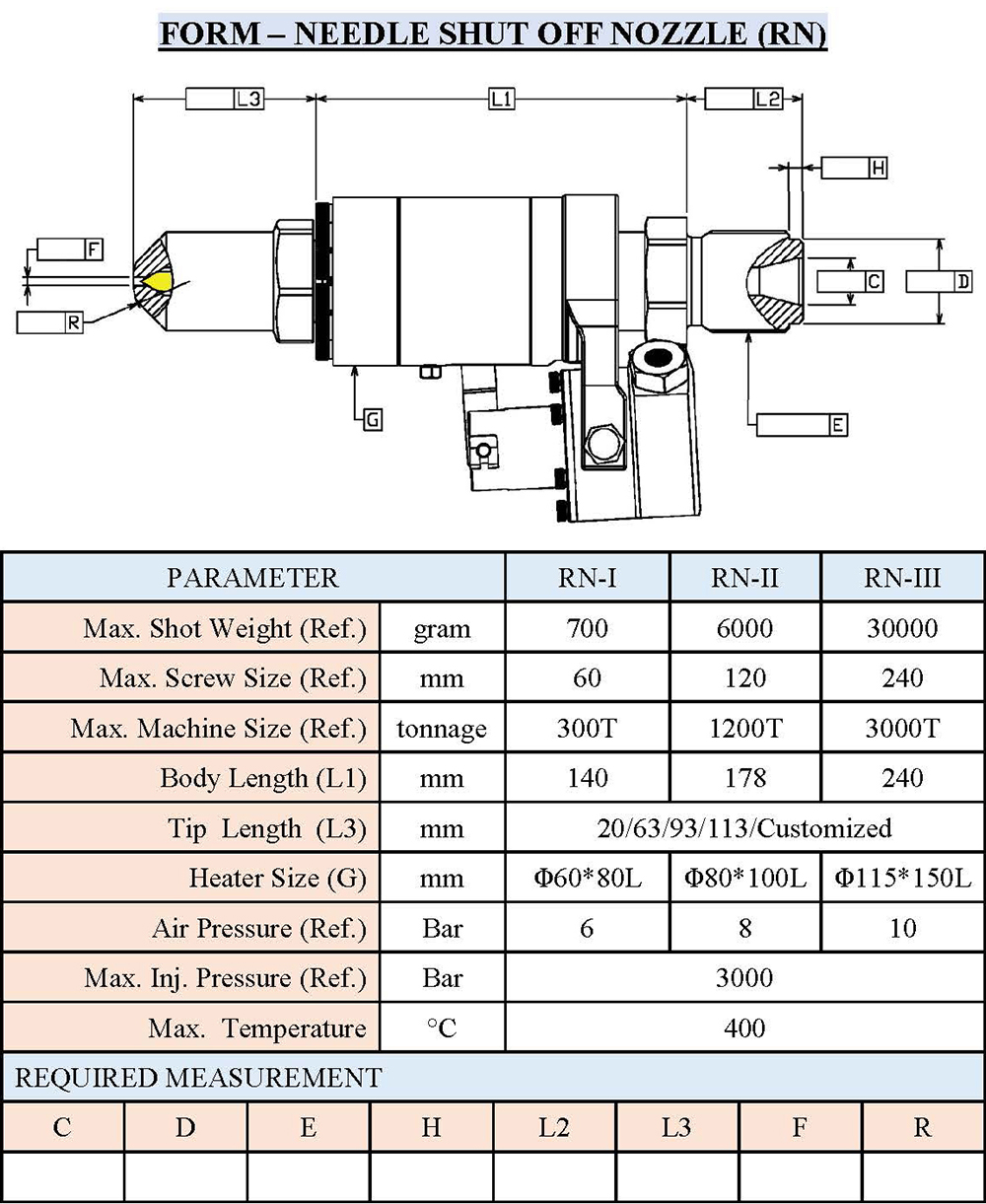

About injection shut off valve

Needle lever shut-off nozzle mainly serves to solve the low viscosity thermoplastic leakage, or to shorten injection cycle time by screw dosing while mould opening, which widely used on high speed injection synchronization and prevent wire-drawing.

Drive can be pneumatic or hydraulic depends on machine convenient.

Mechanism

During storage period of injection unit process, through integrated air or hydraulic cylinder, the inside needle is pushed in axial direction to seal inside nozzle and keep lock-up, so that material won’t pass and leak. And open with machine signal to offer precise injection. During synchronization process, the screw can melt polymer the same time mold opens and save precious time.

Appliance field

Auto parts, Electronic components, Package & Housewares

Technical Index