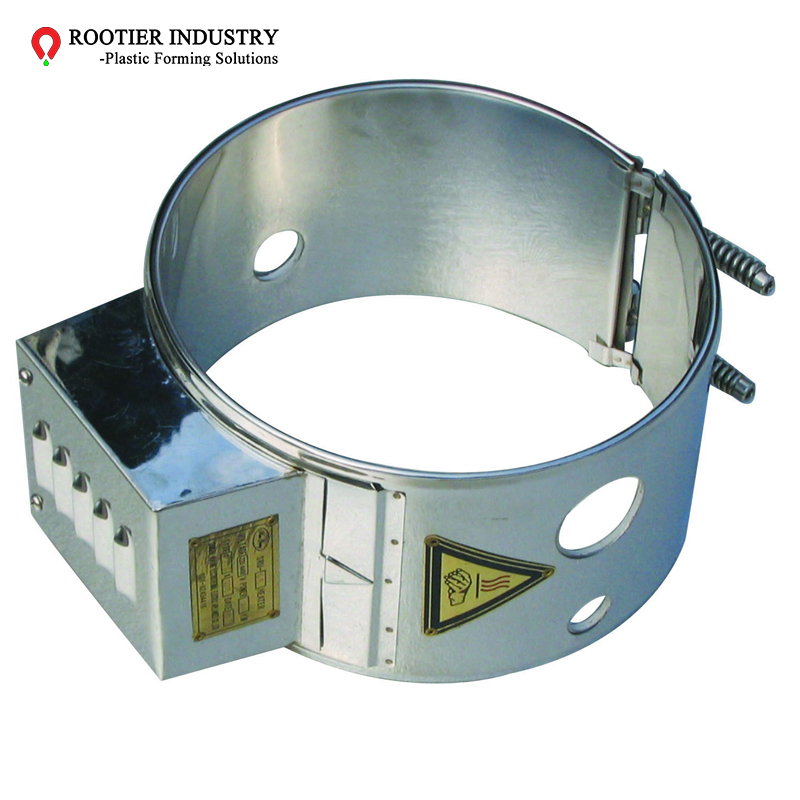

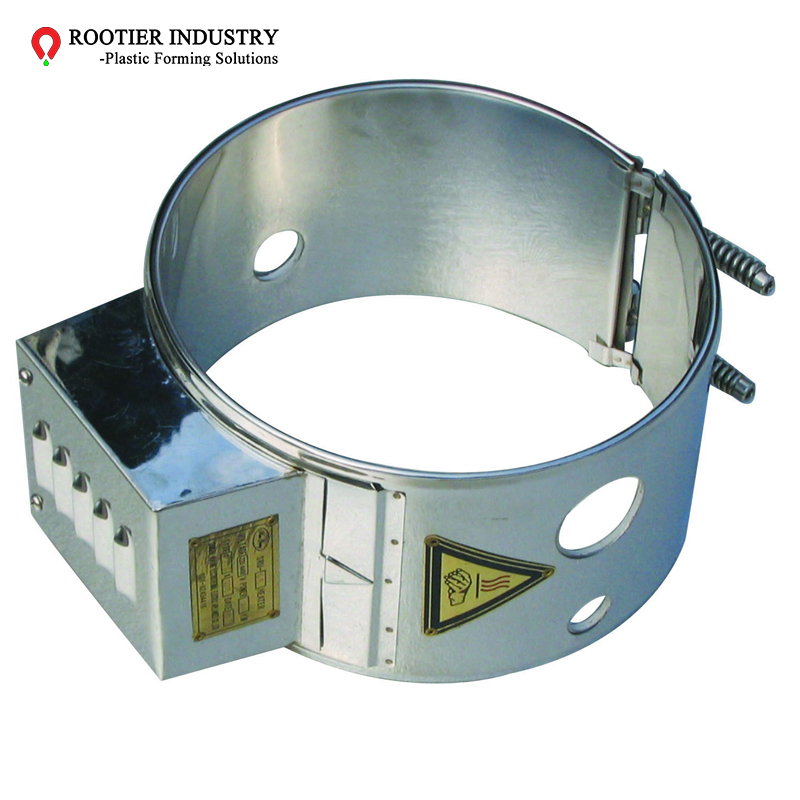

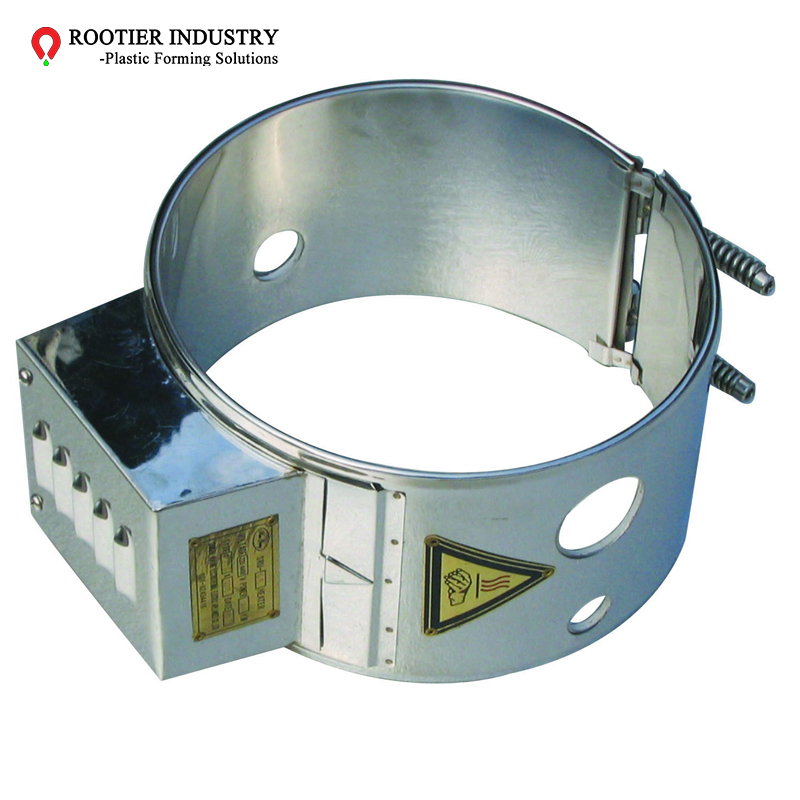

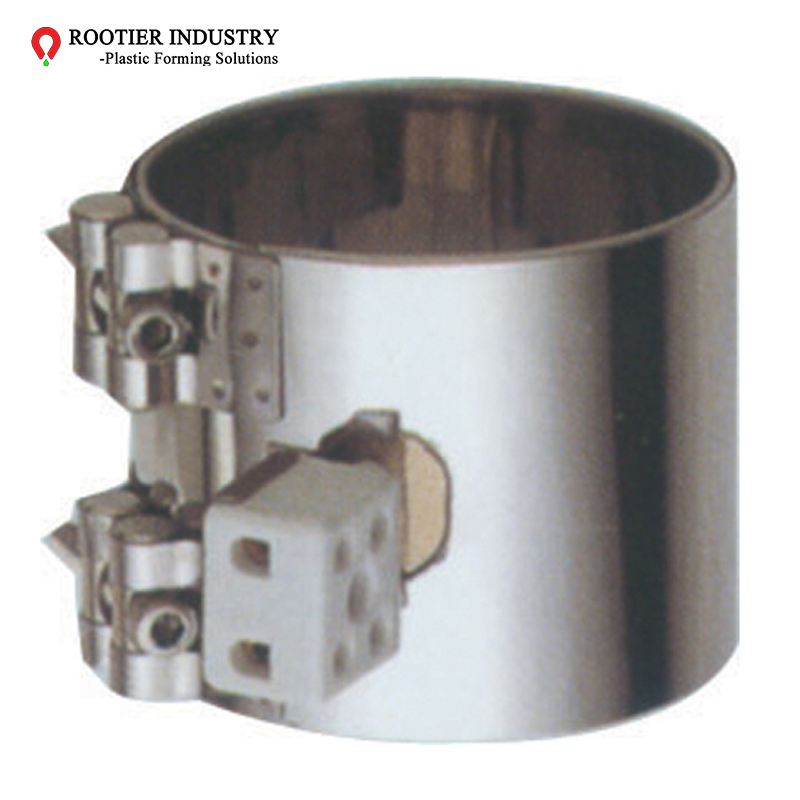

Mica can withstands high voltage spikes, high heat conductivity,resists moisture, is insert to most chemicals and is flexible enough to confirm to the curve of the cylinder without cracking. Its basic structure is twisting the nickel-chrome wire evenly on the mica slice, wrapping up and down by the mica slice to insulate, packing with the copper panel or the stainless steel outside, and then curving it into cylinder.

The heater which has one partition is called single slice form. If it has two partitions it is called double slice form. The standard products all use metal strips to tighten. The carry sons which connect to the power all use the screw type as the standard. Its made- to-order shape can be the line-out type. But for the machine structure it can’t be durable.

Although strip heater has a smooth surface and flexibility, it still needs choosing exact size to ensure the heated material has high efficiency thermal conduction was not good, the outward surface temperature will exceed the allowed. And the service life will be influenced.

Common used size reference

Model | Dimension (mm) | Voltage (v) | Power(w) |

YM-001 | Φ60×60 | 230 | 300 |

YM-002 | Φ110×55 | 230 | 500 |

YM-003 | Φ130×85 | 380 | 1000 |

YM-004 | Φ140×110 | 230 | 1200 |

YM-005 | Φ160×100 | 380 | 1400 |

YM-006 | Φ160×110 | 380 | 1500 |

YM-007 | Φ170×95 | 380 | 1500 |

YM-008 | Φ190×160 | 230 | 2400 |

YM-009 | Φ200×120 | 380 | 2000 |

YM-010 | Φ210×120 | 380 | 2000 |

YM-012 | Φ220×160 | 380 | 2500 |

YM-013 | Φ250×50 | 230 | 1000 |

YM-014 | Φ300×60 | 230 | 1400 |